As we all know, graphene is a new type of two-dimensional carbon material, which has excellent properties such as good light transmission, high thermal conductivity, high electron mobility, and low resistivity. It is used in electronic information, aerospace, high-end equipment, new energy, and environmental protection. And other fields have great application potential. But the current graphene industry is indeed chaotic. There are two main reasons for this: First, the graphene preparation technology is not stable enough, and the preparation cost is high. Second, graphene application products are immature.

The conventional preparation methods of graphene include:

① Micromechanical peeling method, this method can produce high-quality graphene, but has the disadvantages of low yield and high cost, and does not meet the requirements of industrialization and large-scale production. At present, it can only be prepared on a small scale in a laboratory.

②Chemical vapor deposition method refers to the process technology in which reacting substances undergo chemical reactions under gaseous conditions to produce solid substances that are deposited on the surface of a heated solid substrate to obtain solid materials. This method can meet the requirements of large-scale preparation of high-quality graphene, but the cost is relatively high and the process is complicated.

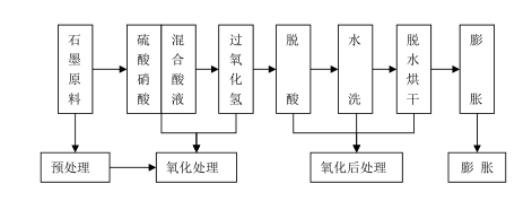

③Redox method refers to the reaction of natural graphite with strong acid and strong oxidizing substances to generate graphite oxide (GO), which is prepared into graphene oxide (single-layer graphite oxide) by ultrasonic dispersion, and a reducing agent is added to remove oxygen on the surface of the graphite oxide. Groups, such as carboxyl, epoxy, and hydroxyl, give graphene. This method can prepare a stable graphene suspension and solves the problem that graphene is not easy to disperse. However, the disadvantage is that large-scale preparation is prone to waste liquid pollution and the prepared graphene has certain defects, which lead to partial electrical properties of graphene. Loss, so that the application of graphene is limited. The solvent exfoliation method is to disperse a small amount of graphite in a solvent to form a low-concentration dispersion, and use ultrasonic waves to destroy the van der Waals force between the graphite layers. At this time, the solvent can be inserted between the graphite layers to perform layer-by-layer peeling to prepare graphite Ene. This method does not introduce any defects on the surface of the graphene during the entire liquid phase exfoliation process, and can prepare high-quality graphene, which provides a broad application prospect for its application in the fields of microelectronics, multifunctional composite materials and the like. The disadvantage is that the yield is very low.

Based on the above, how to develop a system that takes into account the low number of layers, controllable size distribution, abundant raw material sources and low price, simple production equipment, simple preparation process, low energy consumption, high production efficiency, high yield and no pollution The preparation method of industrialized mass-produced high-quality graphene is still a key issue that needs to be solved urgently in the field of nanomaterial preparation technology, and how to apply graphene products to current application devices has become an important topic in the current graphene field.

Our company first solves the key technology of graphene preparation. Using natural graphite as raw material and using physical exfoliation preparation technology, it can obtain graphene powder with high crystal lattice integrity, low impurity content and good dispersibility. The powder is 95%. The above is graphene with less than 10 layers, and the preparation process is simple, which can be adapted to large-scale industrial production. The prepared graphene powder has good batch consistency, stable quality and moderate price, which is very positive for promoting the development of the graphene industry. The role of.